Yes, you do need a dedicated off-road hitch if you tow your trailer off the blacktop, but how do you choose the right one? Here’s absolutely everything you ever wanted to know about the different types of off-road hitches…

Tow a camper, caravan or any type of trailer off-road? If you do, you should consider replacing the age-old 50mm ball for a dedicated off-road hitch that can handle articulation in all planes. This comprehensive guide by Mark Allen explains absolutely everything you need to know about selecting the best off-road hitch to suit your towing needs. It’s long, so settle in, because this is important stuff for anyone who tows a trailer off-road.

While that good ol’ 50m ball does have its place and can handle long-distance travel on and off the bitumen, there are many situations it simply wasn’t designed for, and it can severely hinder your off-road ability, plus be downright dangerous.

In years gone by, there were relatively few options when it came to selecting an off-road hitch, making a choice easy. Within the last five to 10 years though, there has been a glut of hitches swamp the market, most of which have had decent R&D, but some not. Most perform the intended job off-road; some don’t. Some are not ADR approved and some that in fact make hitching and unhitching much easier.

Read on for our ultimate guide as to what’s available to best suit your needs, plus we’ll cover a few golden oldies that are no longer available.

WHAT TO LOOK FOR IN AN OFF-ROAD HITCH

Make sure the off-road hitch can achieve the off-road angles you’re planning for it. Do remember though, many of these hitches state both vertically up and down angles of 90 degrees: while this is great, in reality, you’ll never get your vehicle and trailer combination anywhere close to this. Same goes for the 360-degree rotation ability: unless you roll your 4X4 and your trailer stays on its wheels, you’ll never get that much rotational ability.

Depending on how the rear doors or tailgate opens on your vehicle, make sure it doesn’t hit the off-road hitch or restrict the opening.

Make sure you can easily hitch and unhitch your trailer; not just while on the nice flat concrete driveway at home, but also when you’re on the beach or uneven ground where you can’t easily move the trailer by hand. Some hitches require you to reverse very accurately into position to allow for the hitch to engage – if there’s no room for error or misalignment, you could be stuck not being able to hitch up. A few millimetres out of alignment and they won’t come together… no matter how much you kick or swear at them!

Some off-road hitch designs are (so-called) self-aligning but I can assure you they all have to be within cooee initially to allow this function to happen. The better the self-aligning ability of the coupling, the easier your life will be every time you use your trailer or van.

Try looking for an off-road hitch that doesn’t send the load of the trailer ball weight rearwards of the standard position of the tongue – good luck on this one as most tend to utilise various brackets that force the downward load rearwards.

The greater the number of fiddly clips, buttons, latches and locks, the less simple (and easy) it ends up being in real-life use, especially given the likelihood your hitch will get covered in mud, water and dust. The more gunk it gets on it, the less likely all those fiddly bits will work like they do in the showroom.

Some hitch brands offer override brake systems built into the main body as options; check first if you need that option, especially if you’re updating a hitch onto an old trailer.

Make sure the hitch (or next to the hitch) includes a facility for a handbrake… it’s not funny watching your camper roll away when you unhitch!

Part of the ‘National Code of Practice – Building Small Trailers’ mentions a trailer that doesn’t exceed 3.5-tonnes ATM “must have a quick-release coupling which is designed to be engaged and disengaged without the use of tools. It must be of a positive locking type with provision for a second independent device. The locking must be readily verifiable by visual inspection.” The code does go on with further regulations, but either some coupling manufacturers either haven’t read this code or have been smart enough to get around the loosely written code by slight… let’s just say… bending of the intended rules… you be the judge, eh!

Watch out for all the cheap overseas copies that have hit our shores. While some may have been tested and ADR approved, and some may be designed for our use off-road, I can assure you some fall short of the goalposts and do vary slightly from the original design parameters from which they were copied.

Most of these off-road hitches will offer articulation in all planes that will far outdo anything anyone will ever achieve in real life. I’d go so far as to say if you can test to the maximum angles of this hitch, you’ll end up without the shiny side up.

Happy hitch hunting.

50MM BALL

Yes, a traditional 50mm ball coupling is fine for on-road and flat off-road work, but once the undulating tracks and true off-road work starts; you’re best swapping the standard ball for a dedicated off-road coupling. In fact, there are advantages to not using a 50mm ball even for on-road use.

My personal experience of trying to unhitch a dual axle caravan that had developed axle-twist while reversing into a tight parking spot found me fighting for way too long to unhitch from the 50mm ball. That twisting effect had bound the coupling onto the ball and given the inability to slide directly vertical over the bulge of the ball meant I couldn’t unhitch. Most parallel-walled tow pins, on the other hand, would have allowed the jockey wheel to lift the van off easily. Since then, I’ve vowed never to use a 50mm ball on a caravan.

A 50mm ball offers acceptable horizontal movement, but is particularly restrictive in rotational and vertical angle movement, making for steep descents or ascents into gullies or river banks impossible without damage.

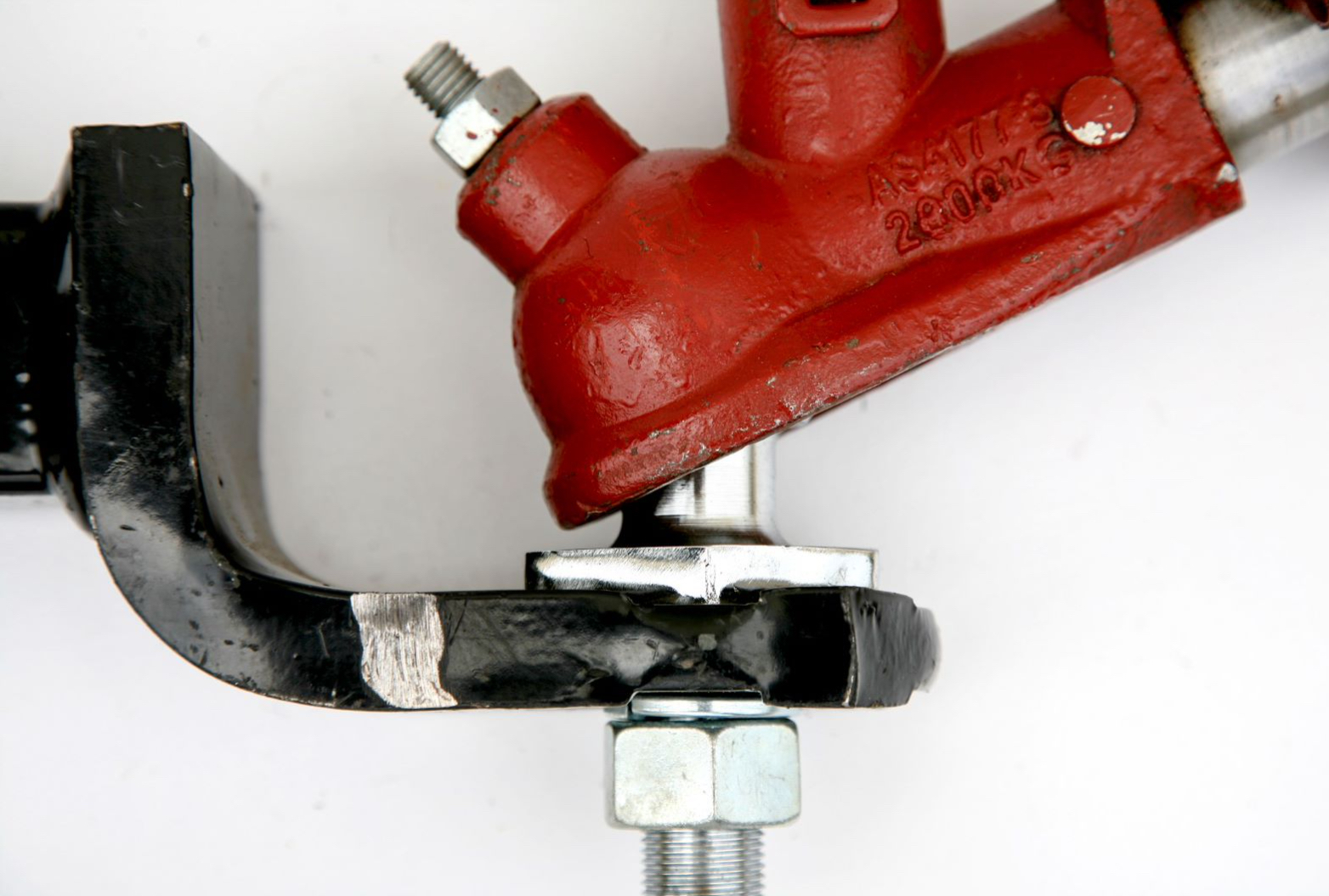

One point to note is that most 50mm ball couplings are adjustable, and most people don’t set them correctly. See the nut and thread protruding from the snout of the trailer hitch – it needs to be adjusted when the hitch is sitting on the ball to rid movement and noise. You’ve still got metal- on-metal, which will produce wear and tear over time, but a 50mm ball should not rattle if adjusted correctly.

Most standard 50mm coupling aren’t particularly low profile, making for damaged rear doors if you’re not careful while opening.

Personally, if you insist on using a 50mm ball, and that’s okay, I’d flick the standard hitch and look at one of the off-road hitches that can be used with the ball.

AL-KO NEW OFF-ROAD BALL COUPLING

Well known for its range of trailer and caravan suspension and parts, AL-KO also has a number of off-road hitches in 2.0 and 3.5-tonnes fixed and override configurations; all of which are ADR compliant.

While the original AL-KO Off-road Ball Coupling is no longer available (it has been replaced by a design similar to the old Hyland product) the New Off-road Ball Coupling still utilises a standard 50mm ball, although clamps on differently to a standard ball coupling.

With its pivoting head, the system is somewhat self-aligning and is unhitched via a lift-up T-piece handle at the top of the main pivoting head. The non-corrosive zinc coating should see the hitch looking good for many years.

A point to note on the original design for making hitching up easier is to remove the round red side-mounted knob to help hold the pivoting head in position; otherwise, you’ll find yourself unnecessarily holding the head up level. Don’t forget to replace it before driving off! The newer design overcomes that teething problem.

One advantage to this hitch is the ability to tow many different trailers that use the 50mm ball, without changing your ball. Other pluses are that the hitch is quite low profile (allowing for use with most tow vehicles’ rear doors), it doesn’t require pins or other locking mechanisms to be used and it can be used with weight-distribution systems.

Website: alko.com.au

AL-KO OFF-ROAD PIN COUPLING

This AL-KO off-road hitch utilises a dedicated tow post rather than a 50mm ball as per the company’s other offering. It needs no locking pins, latches or fiddly levers to aid in hitching and unhitching. A simple depression of the top cap and the positive latching indicator (after which you can remove your hands) allows the raising of the jockey wheel to unhitch the hitch from the pin.

Lowered onto the pin; the integrated positive latching indicator automatically pops out to show a green coloured band amid the surrounding red. This ADR-compliant system double locks and prevents accidental dislodging of the hitch.

Provided the hitch is within close range over the pin prior to lowering, it will pivot and self-centre. If you are beyond the scope of working, the AL-KO Click Lock system will not engage the pin, and the green band does not pop out; a great visual indicator that something is amiss.

A low 83mm hitch height allows for use with most door openings, and the 3500kg rating allows use on most larger campers and caravans too.

Given its anti-corrosion coatings, this hitch should remain faithful for many outback and coastal trips. The integrated seals help keep dust and water from within the main hitch body so ongoing use in adverse conditions should be good.

Website: alko.com.au

ARK XO OFF-ROAD COUPLING

The cast ARK XO 2-tonne and 3.5-tonne couplings offer full off-road articulation in all axes while utilising a standard 50mm ball. Single-handed hitching and unhitching is via the simple top-mounted locking mechanism with inbuilt red and green indicator to ensure the hitch is seated. There’s also a ‘stopper’ to hold the head up level so it can easily drop onto the ball without having your fingers in the way.

Self-aligning via the head pivoting allows the coupling to slide onto the ball, providing the alignment is close to start with. There are no extra pins, locks or parts to use or lose.

The low profile allows rear swing-out doors to open without concern for denting the panels and the package also comes complete with a 50mm ball just in case the one you already have is not quite right, making the whole kit instantly useable.

The 2-tonne unit offers an override system with lockout (can be used as override brakes or electric), while the 3.5-tonne is for electric braking systems only. ARK also supplies a suitable handbrake lever that slips under the coupling when bolting the whole system on.

There are multiple grease nipples to ensure everything rotates smoothly in all axes. Another big plus with the OX series off-road hitches is that they comply with Australian standards, so peace of mind is always with you on the tracks.

Given it uses a 50mm ball; there is no need to switch coupling if you have multiple trailers in use.

Website: arkcorp.com.au

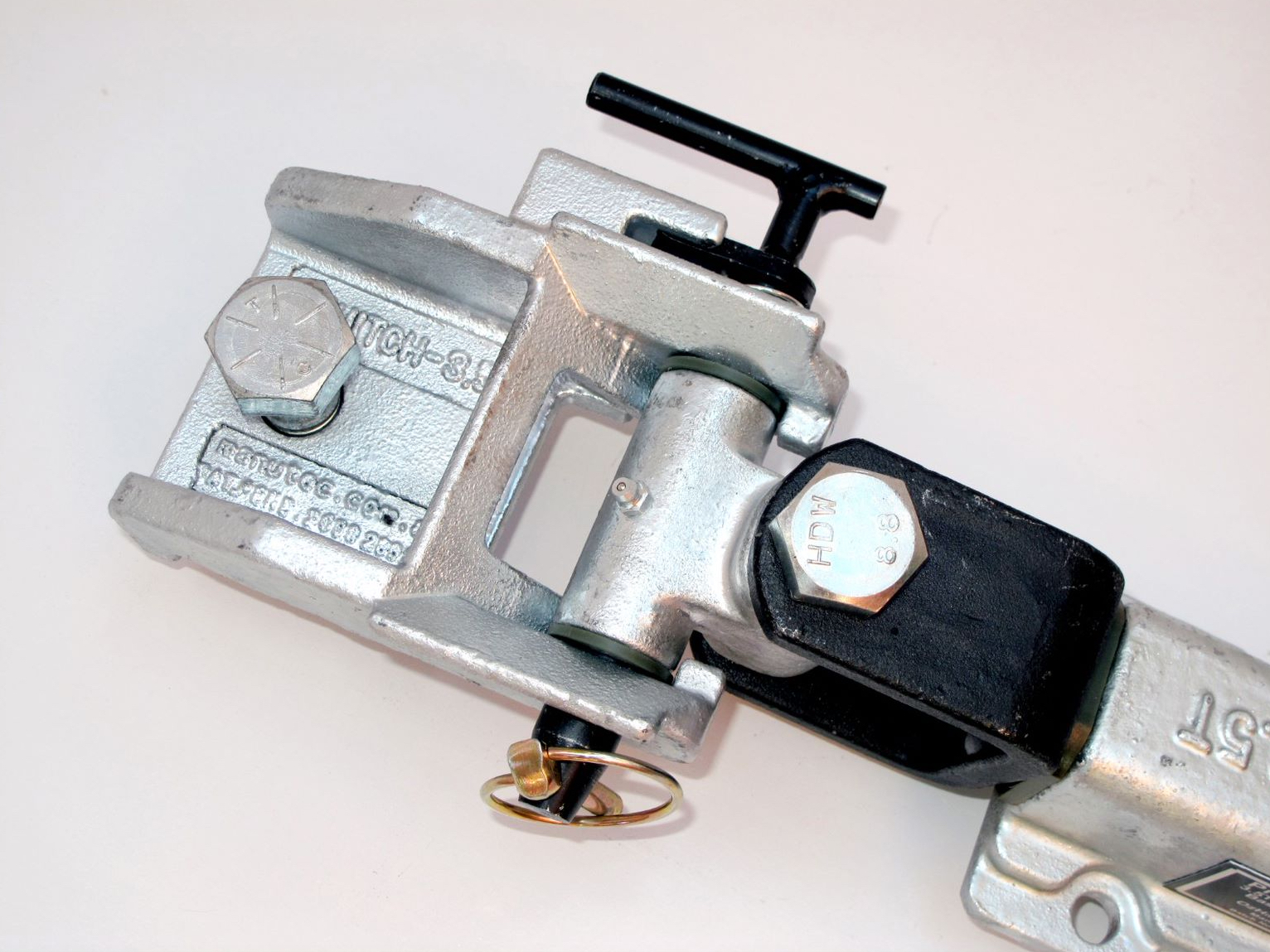

HITCHMASTER AT35 COUPLING

Previously manufactured by Vehicle Components (with a new company name of Cruisemaster) in Queensland, the 3.5-tonne rated AT35 off-road hitch has long since been shelved in favour of the original DO35, which is now up to version three. The AT35 was a crowd favourite along with the poly block hitch types and incorporated a cast pivoting joint which was bushed to prevent rattling, plus a vertical main (spring-loaded) pin which was dropped into position to secure the trailer to the tow vehicle. As well as the standard linchpin that slots into the main pin underneath, the AT35 had extra locking mechanisms to satisfy ADR requirements and to ensure the security of the whole setup.

The AT35 was SA5 coated to resist rust and had optional handbrakes that bolt to the rear of the main body. You can no longer buy the AT35.

Website: cruisemaster.com.au

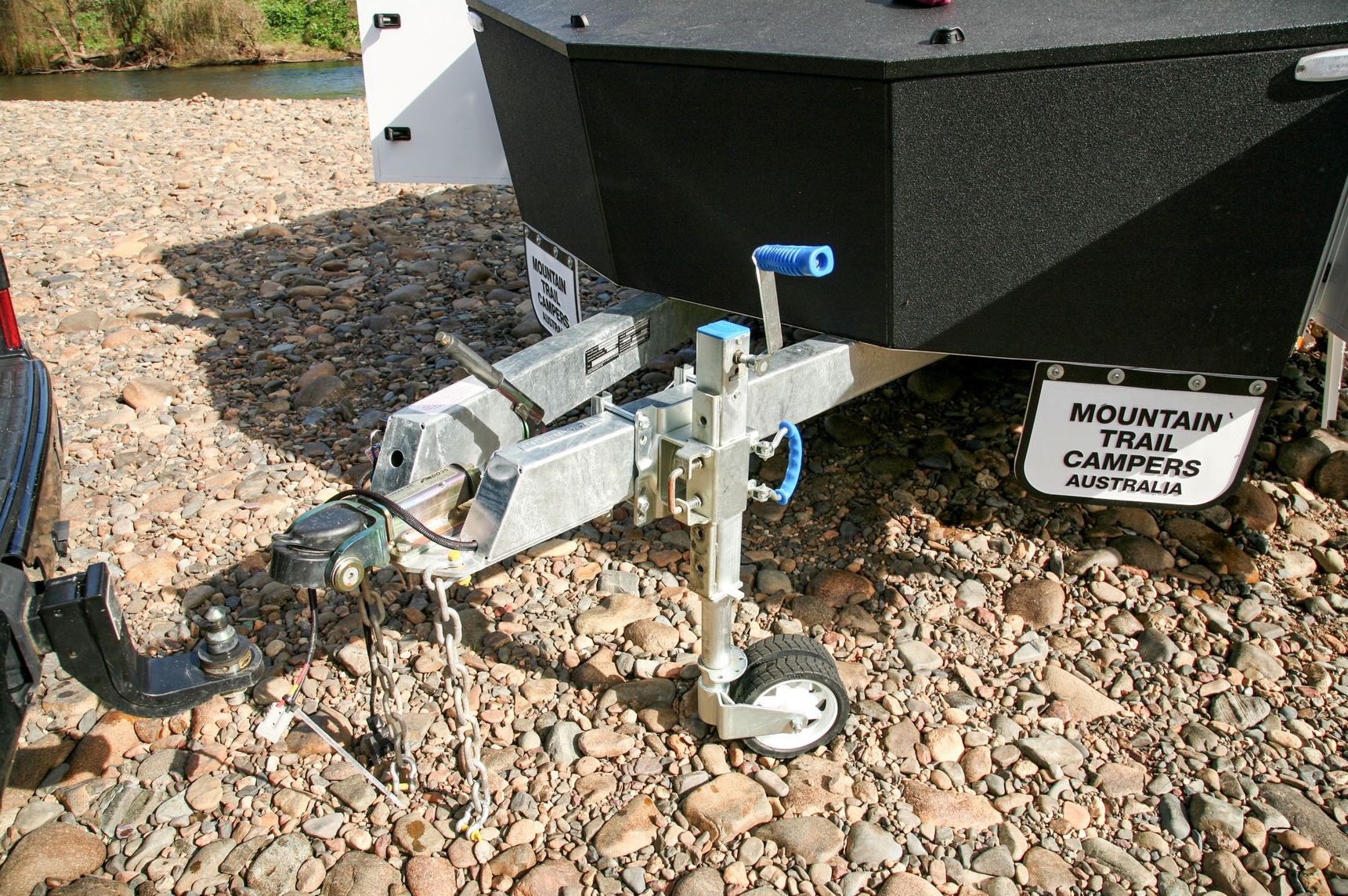

CRUISEMASTER DO35 COUPLING

Queensland based Cruisemaster (previously known as Vehicle Components) is responsible for the design and manufacture of the DO35 (stands for Drop On 3.5-tonne) off-road hitch of which it’s up to version three, which the company claims to be 50 per cent stronger than V2. Plus there is also a higher rated DO45 (4.5-tonne) unit for those who need the higher capacity. The Cruisemaster DO35 unit incorporates a pivoting, self-aligning head that drops onto a dedicated forged towing pin.

Laser-cut designs utilising forged steel, stainless steel and polyurethane, combined with casting methods to ensure precision and strength, 360-degree rotation combined with 70 degrees vertical and horizontal angles, all ensure you’ll tow through almost any angled terrain.

A simple and positive two-stage ADR-compliant locking mechanism ensures fast and safe hitching of your trailer in any terrain while allowing for self-centring as your jockey wheel is lowered. A Checklock cap is also included to ensure positive attachment as well as aiding in keeping dust and water out of the hitch’s workings.

Being such a low profile ensures dent-free use with most tow vehicle tailgates and door openings. Greasable bushings ensure squeak-free workings, while the corrosion-resistant coating should keep your hitch looking like new.

The newer, taller tow pin allows for easy fitting of weight distribution hitches without relying on adaptors.

Early in 2020, Cruisemaster advised us of an upgraded version of the V3 – the V3Plus, which has a few subtle changes driven by customer feedback such as a more intuitive Checklock cap and bumper closing action, increased durability of the front strip, and improved rear webbing that allows fitting under the drawbar.

Website: cruisemaster.com.au

HITCH-EZY

The Hitch-Ezy is one of a few hitches that don’t incorporate a vehicle-mounted receiver that transfers the ball weight of the trailer rearward of the standard towing point. That’s a good thing to keep the downward ‘ball weight’ of the trailer as far forward as possible to reduce the negative cantilevering effect on the rear of your tow vehicle.

The Hitch-Ezy utilises a unique towing post, to which the self-centring head engages onto. This hitch locks into position via a set of three internal, spring-loaded ball bearings. Seals are used to keep dirt, water and grit out of the mechanism to aid in long term use. Hitching and unhitching are exceptionally easy with one-touch operation, keeping fingers well away from any moving parts while operating the jockey wheel.

There are 3.5 and 5-tonne units available, both of which are ADR approved. The Hitch-Ezy incorporates automatic double locking when the trailer is lowered into position, and has no pins, locks or parts to lose while out and about, making for easy use. The complete unit is bushed to provide a rattle-free operation and incorporates padlock holes to deter theft.

This hitch can be removed from your tow vehicle, even under load from the trailer, making for easy operation.

Weight distribution systems are useable via adaptors to suit most setups.

Website: hitch-ezy.com.au

HYLAND COUPLING

While the Hyland coupling (company) is now defunct, it’s worthy of mention as it was one of the earlier, successful off-road hitches available. Noting also, since the company’s closure, there are options from AL-KO and ARK of a similar design, which utilise a 50mm ball.

The main advantage of the Hyland hitch is that it doesn’t require changing from a 50mm ball; meaning one fitting can be used with both your standard on-road trailer and an off-road trailer.

The Hyland coupling is as simple and easy as a standard 50mm coupling to hitch and unhitch. When hitching up, the head will rotate in two planes to aid alignment. One point to note is that a 50mm ball (rated to 3500kg) with a slightly longer shaft should be used to ensure the coupling seats properly. Often, standard 50mm shafts will not allow the coupling to ‘drop’ on far enough, and the unwary will have their trailer parting ways when least expected – there were no safety or warning aspects for this problem built into the hitch.

The Hyland hitch requires the same internal tongue adjustment as a standard 50mm ball hitch via the top-mounted external nut and thread. This ensures a rattle-free firm fitment on the ball.

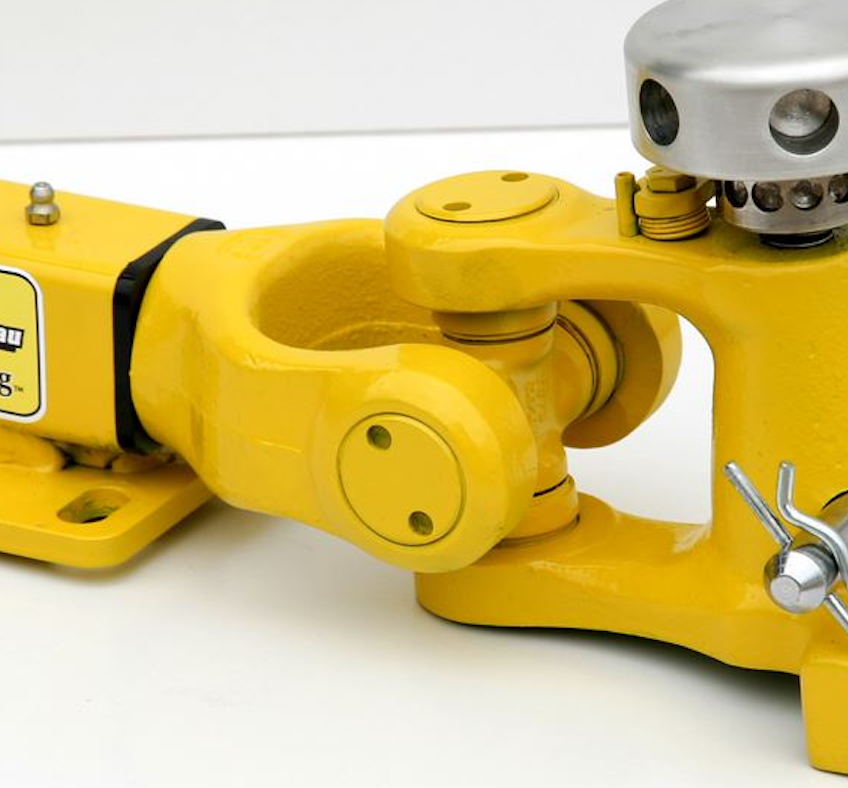

MCHITCH UNIGLIDE COUPLING

McHitch took a new and alternate look at attaching a trailer to a tow vehicle with its drop-on hitch. The main claim to ‘greatness’ is that the point of attachment (of your trailer to the tow vehicle) is different to the point of movement. That is, unlike all others, the trailer is “clamped’ to the vehicle at one point and rotates (in all three axes) at a separate point. This should, according to the manufacturer, prevent wear and tear from ‘pulling’ the weight of your trailer… although that pulling action must take place somewhere along the mechanical line, so you can’t really escape that fact.

The self-aligning and high articulation angles in all planes makes for a great all-round hitch. One downside, which seems to be hypothetical, is some commentators claim a uni-joint was made for rotational forces, not a lateral pull as per this design. Given the design has been tested and passed, plus is ADR approved, I’d suggest the McHitch system should be safe and suitable in its use. Weight-distribution systems can be used, and there are a few options to look at on the company’s website.

The ADR-approved McHitch is also unique in the use of a universal joint (courtesy of a LandCruiser for its 3.5-tonne model and a light truck for its 6-tonne unit) to provide its pivoting point in two planes. The third plane movement is around the horizontal main shaft within the body. There are also 2 and 4.5-tonne versions, as well as adaptors to suit many other couplings – AT35, Treg and Trigg, which allows you to keep one half of an old hitch in service.

The system requires the use of its uniquely shaped towing pin to which the hitch locks onto via a ‘screw-in’ round handle and horizontal, slide-in pin, into which a clevis pin slides into to lock into place.

McHitch offers a range of adaptors for other hitch types to be used in conjunction with its own and also has optional weight distribution brackets for heavy vans while being used on-road.

Website: mchitch.com.au

MCHITCH AUTO COUPLER

Equally distant to anything else on the market as McHitch’s Uniglide drop-on system, the Auto Coupler almost dismays for its uniqueness. The process of hitching your trailer to your vehicle can be done (almost) automatically. There are a few extra things to do before driving away, but the main, initial step of hitching is indeed automatic.

With the system set accordingly, reversing into your trailer sees the primary release lever dropping and locking into place automatically. The jockey wheel has to be wound up, electrical plug connetcted, safety chains attached, and the two extra safety mechanisms engaged. These additional steps almost negate the automatic advantages but, all up, it’s a brilliantly simple and easy system. The automatic system will only work if the horizontal pin is within the receiver plate range. Outside of that range will necessitate the user to adjust either or both the height of the trailer (via the jockey wheel) and the alignment of the trailer to allow proper engagement. Provided the pin and receiver are within range, the system will self-centre as you reverse.

As the driver, you’d need to be mindful while reversing onto the horizontal pin; bumping it too hard may well damage the trailer, your vehicle or perhaps send your trailer off on a solo mission – make sure the handbrake is firmly engaged!

McHitch has successfully refined a hitching system found in the trucking industry; almost all ‘Dog’ and ‘Pig’ trailers are hitched via a similar mechanism. McHitches version eliminates all rattles and coarseness to provide a smooth towing experience. The Auto Coupler is ADR approved and there are kits from 2, 3.5, 4.5 to 6-tonne. Handbrake kits are also available for most of his kits.

Website: mchitch.com.au

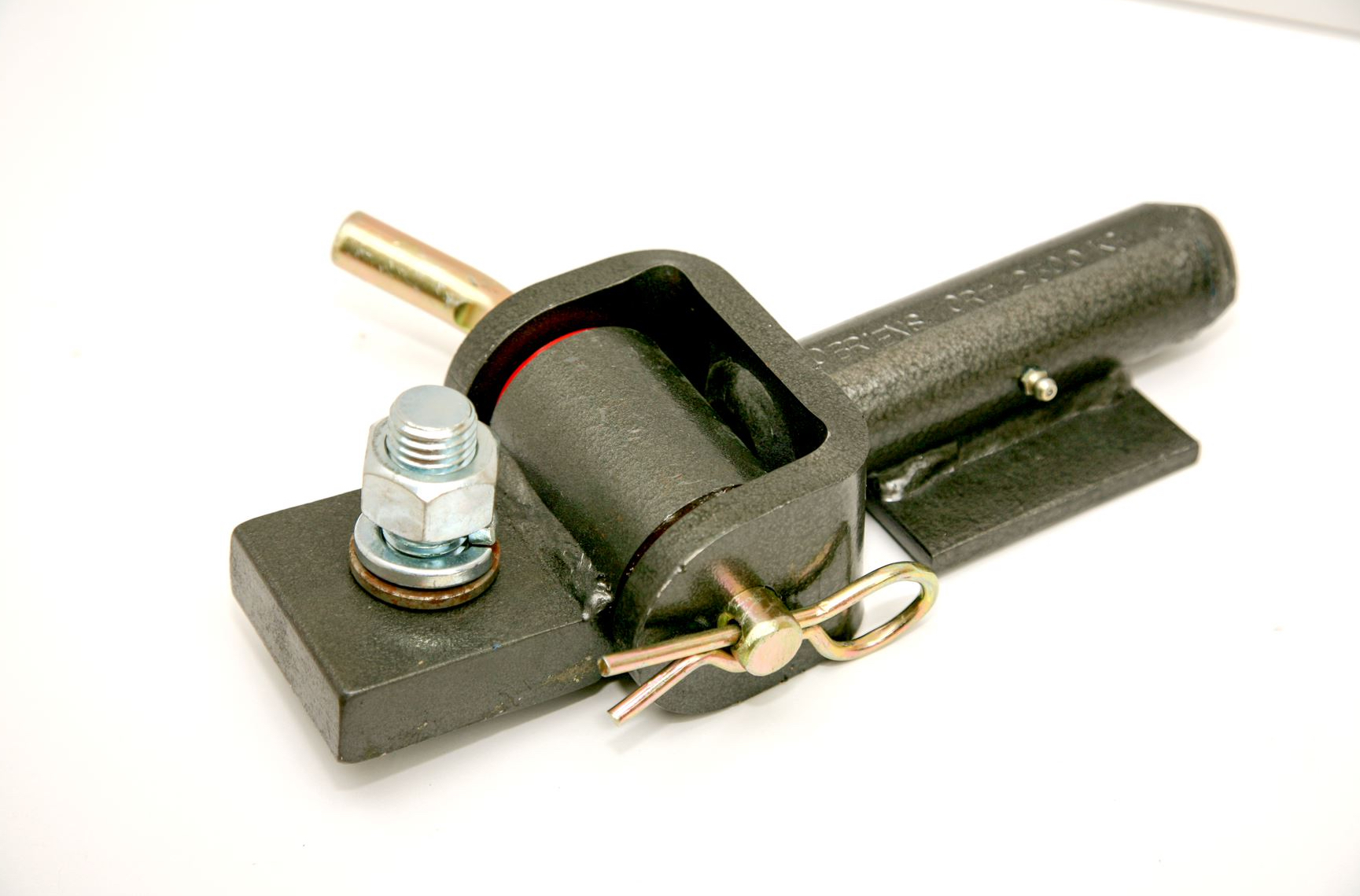

ORAC HITCH

The Orac off-road hitch is Australian made by O’Brien’s Camper Trailers in Victoria and is a super-simple system that allows for extremes of articulation in all directions, is rated at 2.5-tonnes and comes as a weld-on option only.

Once the horizontal main pin is inserted, a side-mounted clevis pin keeps it all together – done and finished, nothing else to do. The only thing needed for easy hitching is to ensure the height of the trailer (via the jockey wheel) is spot on to allow the pin to slide in unhindered without rubbing on the bushes within the pivoting head.

The horizontal pivoting action is via a solid metal bush positioned where the vertical bolt attaches the whole unit to the tow vehicle. The 90-degree vertical movement (up and down) is via the main (bushed) pin, while the rotational motion is via the main shaft – three simple axis movements.

The bolt attaching the unit to the tow vehicle can be installed pointing either up or down to reduce potential damage to the thread.

Website: obrienstrailers.com.au

OZHITCH

The OzHitch has overcome some of the older poly block style hitch problems. Firstly, the self-alignment into a cradle head makes life much easier when hitching up. Once the trailer section is nestled into the cradle, there is no ‘fiddling’ necessary with the jockey wheel to get the correct height. Once it’s in, it’s in! Same goes when unhitching; the trailer is actually resting in the cradle, so pin removal is easy.

Next advantage, the pin slots in horizontally instead of vertically, making the job easier to see and accomplish. The main pin is spring-loaded and locks into a ‘gate’, plus it’s also secured by a traditional linchpin.

One point I do like about this hitch is the ability to mount the bolt that secures the whole show to the tow vehicle pointing upwards instead of downwards. This increases underbody clearances, and also reduces the chances of the thread being damaged – as its pointing up, not down.

The OzHitch is ADR approved and rated at 3500kg. It’s got easily replaceable bushes to ensure a quiet ride and is as simple as they get while being very clever in its dedicated off-road recreational design parameters. Being as simple as it is, it also allows for bush remedies in that you can use a bolt or wire to double as the main pin or linchpin should you lose either.

Website: ozhitch.com.au

POLY BLOCK

The Trigg and Treg brands of poly block hitches represent the Australian made versions and are the originals with Treg dating back to 1947 and the Trigg foundry near on a century from 1925. Given this hitch type is the most often copied, be aware of non-ADR approved versions, some of which seem okay, some not. Poly block hitches are restricted in their vertical up and down movement (about 70 degrees) via a small pin in the rear of the block and the main safety pin can (at times) foul on the swivel head. They also cannot tackle some compound articulation without binding; that is, combining some horizontal and some vertical movements at the same time.

The poly block hitch utilises a vertical safety pin that drops into the main towbar bracket, through the poly block and is secured by a linchpin at the bottom. The main poly block provides good damping between trailer and vehicle, and also incorporates a metal sleeve within, which the main pin slides on and, to this day, still represents a good off-road hitch option.

The main downside is aligning the hitch while on uneven ground or soft sand where the trailer can’t be pushed by hand. Unless you get the holes perfectly aligned, you can’t slide the locking pin in… regardless of how much yelling you do! Raising and lowering of the jockey wheel is often needed to help with alignment to allow the pin to drop freely (or be removed) into position.

The poly block style hitch is reasonably simple in its workings with not much to go wrong. Always ensure you have a few extra linchpins, although a nail or length or wire can always get you out of trouble if you lose the dedicated pin. Poly block couplings have various weight ratings and come in many braked and unbraked guises.

Websites: tregtrailers.com.au and triggbrs.com.au

RING AND PINTLE

While not used too much within the camper trailer industry, we’ll include the Ring and Pintle for general interest. These hitch types are more utilised in commercial applications and small trucks and rarely used for camper trailers or caravans as they allow a great deal of knocking and clanging which also produces a lot of wear with metal-on-metal rubbing.

Notably, Cruisemaster manufactures its version that incorporates a rubber insert to eliminate all the noise and wear problems, and some offer a combination Hook and Pintle with a 50mm ball… perhaps the Hook and Pintle will make a comeback!

LEGALITIES

One of the main attributes you must consider when choosing an off-road hitch is legalities. Yes, choose a hitch that has a high enough load rating, but also ensure it is ADR approved – it should be stamped onto the main body of the hitch. Remember, if it’s not ADR approved, your insurance may well be null and void in the event of a claim after an accident.

1 comment

Thanks for your great article.

Our new van has the standard 50mm ball coupling but under tension it can be difficult to release.

I’d like to keep the 50mm for ease and was wondering which of the 50mm ball couplings would be easier to release under tension.

I like the idea of the ARK XO OFF-ROAD COUPLING

Thanks again for your great article

Mike